Before I talk about Apliweld Secure +, which is the most efficient and safest exothermic welding system in the market, perhaps I should start with exothermic welding itself.

What is exothermic welding?

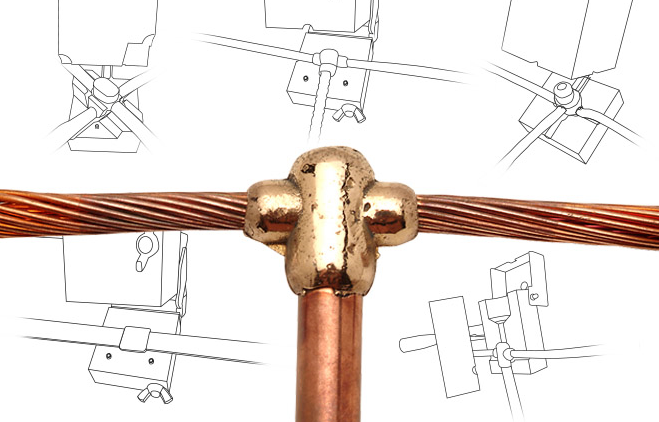

Exothermic welding, also known as aluminothermic or copper-aluminothermic welding, is a process that permanently connects metallic conductors together on a molecular level by the way of a chemical reaction between aluminium & copper oxide. The result of the exothermic weld is a high-quality electrical connection, where the conductors convert into a unique inseparable piece. In this sense, an exothermic welding connection is much better than a mechanical connection, because it is a perfect conductor of current.

Benefits of exothermic welding

- The connection has equal or higher electrical conductivity than the conductors themselves

- Welding does not degrade throughout time and is resistant to galvanic coupling

- Withstands repeated current impulses

- Resistance never increases

- Higher mechanical and crush resistance than the conductors themselves

What is Apliweld Secure +?

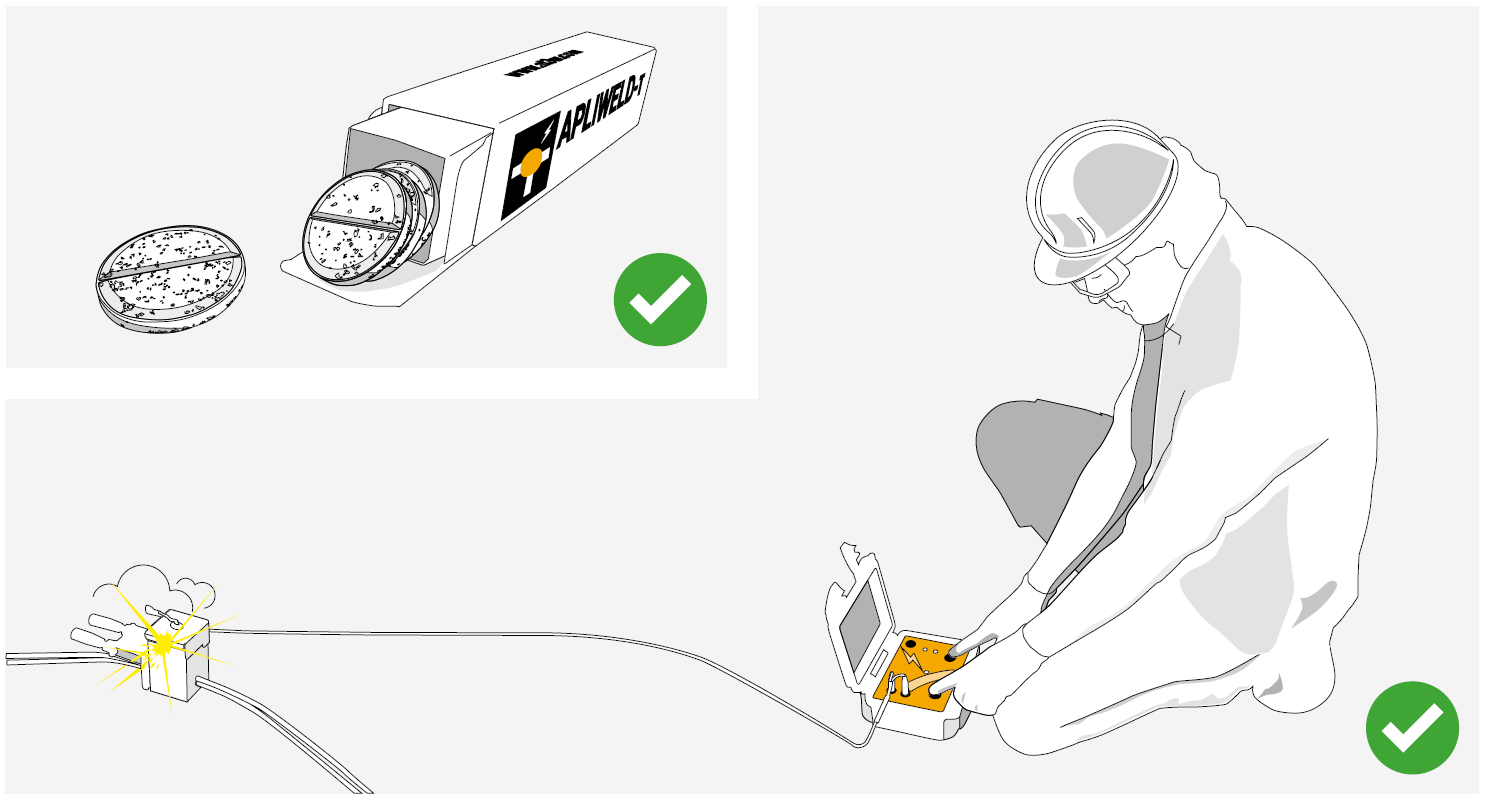

Apliweld Secure + is the innovative, unique exothermic welding system from Aplicaciones Tecnológicas which replaces the traditional welding powders (and all of the variety of sizes/weights) with a welding tablet compound and also replaces the activation of a manually applied spark via a flint gun with remote activation using an electronic ignition unit/Bluetooth starter.

Traditionally, exothermic welding required the user to have multiple cartridges with different powder weights for carrying out the various connections. Once the conductors were inserted in the graphite mould, the welding compound and the reactive powder (usually a flammable compound) were poured into the crucible. Then a flint gun, applied manually to the starting powder at arm’s length produced a spark triggering the exothermic reaction.

Apliweld Secure + benefits

- Eliminates the need for numerous varieties of welding size powders - One welding compound reference for every weld (The powder format requires more than 10 different references to cover all the different welding techniques. In the tablet format it is all reduced to one, two maximum!)

- Reduction of stock volume / choices

- Can be easily stocked as has no shelf life and is non flammable

- Can be used in windy conditions, you always get zero powder spillage! The wind doesn´t affect the charge manipulation. Due to the compact tablet format, they don’t blow out.

- Minimises possibility of user error – every mould engraved with components/materials to be used

- Reduced wastage from cartons, cups etc.

- Much safer to use - Has electronic ignition unit/Bluetooth starter as opposed to flint gun

- The electronic initiator, with remote ignition system, prevents the operator from being exposed to any flammable risks

- Prevents the risk of burns by projection of materials

- Avoids the risk that transport, manipulation and storage of flammable products involve

If you would like any more information, would like to discuss the Apliweld Secure + system or would like a demo so that you can view the system for yourself then please don’t hesitate to contact your local Jointing Tech office or representative.

Guest blog by Jason Leatherland, UK Key Account Manager, Aplicaciones Tecnológicas